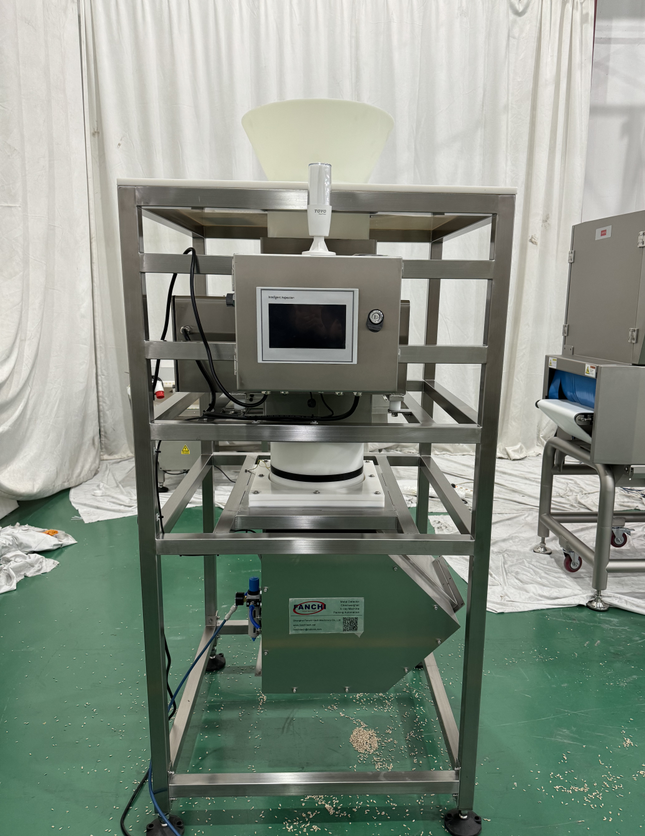

FA-MD SeriesBulk Gravity MetalDetector: Safeguarding Bulk Food Processing from Contamination Risks

For bulk food processors—from cocoa bean roasters to snackingredient manufacturers—unpackaged, free-flowingproductionstagespose a critical, non-negotiable risk: metal contamination. Whether from equipmentwear, rawmaterial impurities, or process-related debris, metallic contaminants can triggercostlyproductrecalls, HACCP non-compliance, and irreversible damage to brandtrust. That’s why North American Cocoa Producers Ltd. (NACP)—a leading supplier of chocolatechips and cocoa derivatives to North America’s top bakeries—partnered with Shanghai Fanchi-tech Machinery Co., Ltd. to deploy our FA-MD SeriesBulk Gravity MetalDetector. Engineered exclusively for the unique demands of bulkprocessing, this precision solutioneliminates contamination risks at critical control points, as validated by NACP’s industry-leading workflow.

The Challenge: Mitigating Contamination in Bulk Food Processing

Before partnering with Fanchi-tech, NACP faced pain points that plaguebulk food processors globally—all centered on unmanaged metal contamination risks:

- Free-flowing cocoa beans and semi-finished chocolatechips were vulnerable to metal contamination across unpackaged stages, with no consistent detection mechanism at key process points.

- Legacyequipmentlacked automated validation and contamination data tracking, making HACCP audits cumbersome, reactive, and prone to compliance gaps.

- Metallic finalpackaging meant post-sealingmetal detection was impossible—requiring an airtight pre-packaging inspection solution to ensureproductsafety.

- Contamination incidents riskedcostly downtime, batchrejects, and damage to relationships with top bakery clients.

The Solution: FA-MD SeriesBulk Gravity MetalDetector—Engineered for Bulk Food Safety

Fanchi-tech’s FA-MD Series is purpose-built to address the unique challenges of free-flowingbulk products, embedding proactive contamination control into every stage of NACP’s workflow. Designed for seamless integration and uncompromising sensitivity, it delivers industry-leading protection without disrupting throughput:

1. Gravity-Fed Design: Optimized for BulkFlow Rhythms

The FA-MD Seriesfeatures a gravity-fed configuration that aligns perfectly with unpackaged processing lines:

- Productflows via food-grade, corrosion-resistantpipesdirectly through the detector’s searchhead aperture—eliminating the need for complex conveyors or process modifications.

- No disruption to throughput: The designmatches the naturalflow of bulk ingredients (e.g., cocoa beans, powder, semi-finished chips), ensuringproductionefficiencyremains uncompromised.

- Suitable for harshprocessing environments: Built to withstanddust, moisture, and continuous use—critical for bulk food facilities handling high-volume, free-flowing products.

2. Industry-Leading Detection Precision: Catch All Metallic Contaminants

At the core of the FA-MD Series is a advanced three-coil detection mechanism that delivers unmatched sensitivity to ferrous, non-ferrous, and stainless steel contaminants—even in challenging bulk matrices:

- A central transmitter coil (powered by a high-frequency oscillator) generates a stable electromagnetic field, optimized for bulk food applications.

- Two symmetric receiver coils (equidistant from the transmitter) cancelinduced voltages when balanced—producing zero output if no metal is present.

- Any metallic contaminant (e.g., tinymetal shavings, wirefragments, stainless steel particles) disrupts the electromagnetic field, triggering an unbalanced signal.

- High-speedrejectmechanism: Contaminatedproduct is diverted in milliseconds, minimizing waste of high-value ingredients and preventing cross-contamination of subsequentbatches.

3. Strategic Placement: HACCP Critical Control Points (CCPs)

Following HACCP best practices, Fanchi-tech positioned the FA-MD Series at two non-negotiable CCPs to create a “dual line of defense” against contamination:

1. RawIngredientInlet (Foundational CCP)

Bulk cocoa beans are gravity-fed from silos through the FA-MD Series before enteringroasting/grindingstages. This catches contaminants early—rejectingimpairedproduct before value is added, preventing impurities from dispersing into larger batches, and eliminatingrisks at the source. For NACP, this stepeliminated the threat of rawmaterial-related contamination before it could impact downstream processes.

2. Pre-PackagingFinal Check (Last Line of Defense)

Between the processing line and vertical form-fill-seal (VFFS) machine, the FA-MD Seriesperforms a final contamination check—critical for product destined for metallic packaging (where post-sealing detection is impossible). This ensures no contaminants slip through to finished goods, guaranteeing metal-free output before sealing.

HACCP Compliance & Data-Driven Contamination Control

The FA-MD Series is engineered to streamlineaudits and enable proactive maintenance—key for bulk processors navigating strict regulatory requirements:

Fanchi Performance Validation (FPV)

Automatically prompts operators to conduct sensitivity checks at pre-set intervals (every 4 hours at NACP). A yellow indicator light signals pending tests; a red light activates (and logs the lapse) if uncompleted within 30 minutes. This ensures no gaps in detection performance, keeping compliance on track without manual oversight.

Fanchi SmartNet Centralized Data System

All FA-MD units are networked to a central PC, auto-collecting sensitivity test results, rejectlogs, and contamination data. This enterprise-level monitoring capability allows NACP to:

- Track contamination trends (e.g., a spike in rejects signals equipmentwear, prompting proactive maintenance).

- Storeaudit-readyrecords for FDA, HACCP, and SQF 2000 compliance—eliminating the need for manual documentation.

- Identify high-riskprocessstages (e.g., rawmaterialbatches with frequent contamination) to optimize upstream quality control.

CustomerVerdict: “Proactive Contamination Control That TransformsAudits & Safety”

“The FA-MD Series has redefined how we manage contamination risks,” says Mark Thompson, NACP’s Engineering & MaintenanceManager. “Before Fanchi-tech, we were reactive—chasingissues after they occurred, with no clear visibility into contamination sources. Now, the gravity-fed FA-MD catches contaminants early, SmartNet lets us spottrends before they become problems, and compliance is seamless. We haven’t had a single contamination-related incident or recall since installation, and HACCP audits are now a straightforwardprocess.”

Since deploying the FA-MD Series:

- NACP reduced contamination-related downtime by 100%.

- Eliminated all contamination-related batchrejects and customer complaints.

- Streamlinedauditpreparation time by 70% (thanks to Fanchi SmartNet’s automated data logging).

- Achieved 100% compliance with FDA and HACCP standards for metal contamination control.

Why Fanchi-tech’s FA-MD Series for Bulk Food Processing?

For processors like NACP, the FA-MD Series delivers more than a metaldetector—it’s a strategic investment in safety, compliance, and brandreputation:

- Bulk-Specific Engineering: Gravity-fed design and food-gradeconstruction are tailored to the unique demands of unpackaged, free-flowing products.

- Uncompromising Sensitivity: Detects ferrous, non-ferrous, and stainless steel contaminants—even in challenging bulk matrices (e.g., dusty cocoa powder, dense bean batches).

- Seamless Integration: Syncs with existingproduction lines, requiring no costly reconfiguration or downtime during installation.

- Data-Driven Compliance: FPV and SmartNet simplifyaudits and enable proactive riskmanagement.

- Global Certification: Fully certified to FDA, EU 178/2002, and HACCP standards—ready for international markets.

Take the Next Step: Secure Your BulkProcessing Line

Don’t let metal contamination risk your business, compliance, or brandtrust. Contact Kerry Wang (Food ProcessingEquipmentSpecialist) to schedule a free virtual demo of the FA-MD Series—we’ll test your bulkproductsamples (free of charge) to tailor a contamination control solution for your specific workflow.

Shanghai Fanchi-tech Machinery Co., Ltd.

Email: fanchitech@outlook.com

Website: www.fanchitechnology.com

Post time: Dec-15-2025