FA-XIS Series Bulk X-Ray Inspection & Free Fall Metal Detectors: 100% Contaminant-Free Pulses for Global Food Producers

For dried pulse processors—specializing in peas, beans, and lentils—non-metallic contaminants like stones (the most persistent threat) and hidden metal fragments can shatter brand reputation and fail strict HACCP compliance. This is why UK Pulse Masters Ltd.—a leading British processor supplying premium pulses to global food manufacturers (including major ready-meal brands)—partnered with Shanghai Fanchi-tech Machinery Co., Ltd. to deploy our FA-XIS Series Bulk X-Ray Inspection System and FA-MD Free Fall Metal Detectors—a dual solution engineered to eliminate even the most elusive contaminants.

The Challenge: Chasing 100% Contaminant-Free Pulses

Before choosing Fanchi-tech, UK Pulse Masters faced critical gaps that mirrored industry-wide pain points:

- Their six existing de-stoner systems removed 99.9% of stones, but the remaining 0.1% (stones indistinguishable from pulses in color, weight, and texture) led to occasional customer complaints—risking their premium brand status.

- Legacy metal detectors could not identify non-metallic hazards (glass, calcified bone, high-density plastics) or detect metal fragments hidden within pulse batches.

- Tightening HACCP and global food safety regulations demanded proactive, foolproof inspection—far beyond what manual checks or basic equipment could deliver.

- With a daily processing capacity of 200+ tons, the solution needed to match high throughput without slowing production.

Integrated Solution: FA-XIS Series Bulk X-Ray + FreeFall Metal Detectors

Fanchi-tech’s tailored combination addressed UK Pulse Masters’ unique needs, delivering comprehensive contamination control across their workflow:

1. FA-XIS Series Bulk X-Ray Inspection System: The Final Line of Defense Against Non-Metallic & Metallic Hazards

Engineered for bulk dry goods like pulses, the FA-XIS Series solved the core challenge of stone contamination while adding multi-hazard detection:

- All-Category Contaminant Detection: Cutting-edge X-ray technology identifies both metallic (ferrous, non-ferrous, stainless steel) and non-metallic contaminants—stones, glass shards, calcified bone, high-density plastics, and rubber—eliminating the 0.1% gap left by de-stoners.

- High-Speed Throughput: Designed to keep pace with 200+ tons/day processing lines, the FA-XIS Series operates at speeds that sync seamlessly with sorting and grading equipment—no production bottlenecks.

- Multi-Functional Inspection: Beyond contamination control, it detects product defects (e.g., misshapen pulses, inconsistent size) and enables zone mass measurement and component counting—adding value beyond basic inspection.

- User-Friendly Design: Features a high-speed USB sensor, intuitive graphical touchscreen display, and Windows-based operating system—ensuring operators (even with minimal training) can maximize machine performance.

- Hygienic & Robust Build: Smooth, crevice-free surfaces (304 stainless steel) resist dust and debris common in pulse processing, while a durable frame withstands 24/7 industrial use.

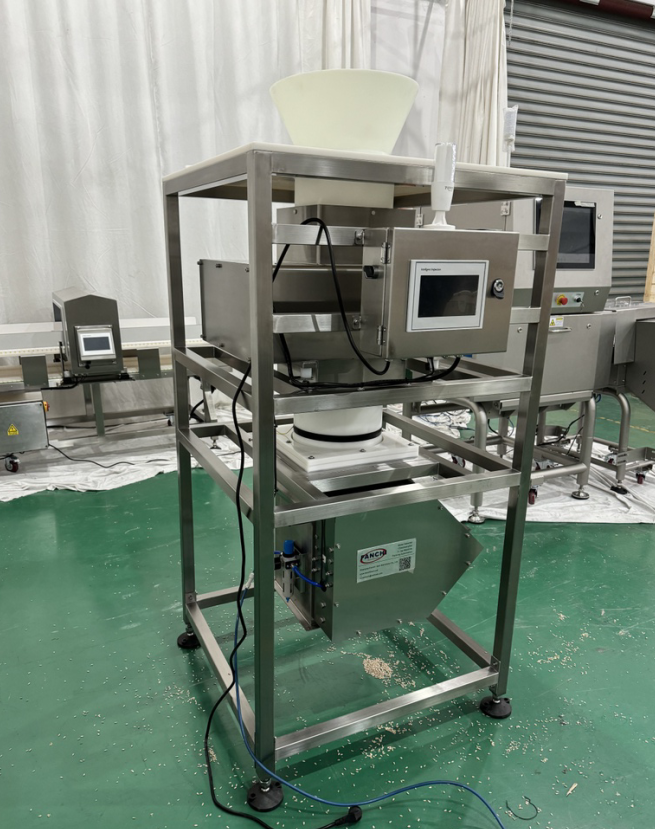

2. FA-MD Free Fall Metal Detectors: Post-Processing Metal Contamination Control

Complementing the FA-XIS Series, two Free Fall Metal Detectors installed at the end of the processing line target metal fragments introduced during sorting, cleaning, or grading:

- Free Fall Design: Pulses flow freely through the detector’s aperture via gravity-fed chutes, ensuring full product coverage without disrupting flow.

- Precision Metal Detection: Calibrated to identify even small metal contaminants (e.g., shotgun pellets, equipment wear fragments) that may occur during processing—adding a critical secondary check for metallic hazards.

- Dedicated Reject Signals: Works in tandem with the FA-XIS Series to send separate reject signals for different non-conformities (e.g., stones vs. metal)—keeping contaminated products segregated and minimizing waste.

Customer Success: From 99.9% to 100% Contaminant-Free

Since deploying Fanchi-tech’s integrated solution, UK Pulse Masters has transformed its quality control:

- Eliminated all stone-related customer complaints (down from 3–4/quarter to 0).

- Achieved 100% compliance with EU, Middle Eastern, and Asian food safety regulations—expanding their export reach to new markets.

- Maintained high throughput (200+ tons/day) without sacrificing inspection accuracy.

“The FA-XIS Series is a game-changer for our business,” says James Harrison, Senior Plant Manager at UK Pulse Masters. “Our de-stoners did a great job, but we needed that final layer of protection to hit 100% contaminant-free—and this system delivers. It’s easy to use, reliable, and spots every stone or metal fragment we throw at it. We’re thrilled with its performance.”

Darryl Carter, Joint Owner of UK Pulse Masters, adds: “When we approached other suppliers, they dismissed us as a ‘small processor’—but Fanchi-tech listened to our needs and delivered a custom solution that fit our line perfectly. We’ve never looked back.”

Why Fanchi-tech for Pulse & Bulk Food Processing?

For processors like UK Pulse Masters, our FA-XIS Series and FA-MD Free Fall Metal Detectors offer unmatched value:

- Dual-Hazard Protection: Combines X-ray inspection (non-metallic + metallic) and Free Fall metal detection (targeted metallic checks) for comprehensive coverage.

- Bulk-Specific Engineering: Built to handle the unique demands of dry, free-flowing products like pulses—high speed, dust resistance, and unobstructed flow.

- User-Centric Design: Intuitive touchscreen and simple setup minimize training time and operational errors.

- Global Compliance: Fully certified to HACCP, EU 178/2002, and FDA standards—ready for international export markets.

- Custom Integration: Tailored to fit existing processing lines, no costly reconfiguration required.

Take the Next Step: Secure Your Pulse Production Line

Don’t settle for 99.9% purity—aim for 100%. Contact Kerry Wang (Food Processing Equipment Specialist) to schedule a free virtual demo of the FA-XIS Series and FA-MD Free Fall Metal Detectors—we’ll test your pulse samples (free of charge) to design a solution that meets your unique needs.

Shanghai Fanchi-tech Machinery Co., Ltd.

- Email: fanchitech@outlook.com

- Website: www.fanchitechnology.com

Post time: Dec-17-2025