Fanchi-tech’s FA-MD Metal Detectors & FA-CW Checkweighers Steal the Show at China Food Processing Expo

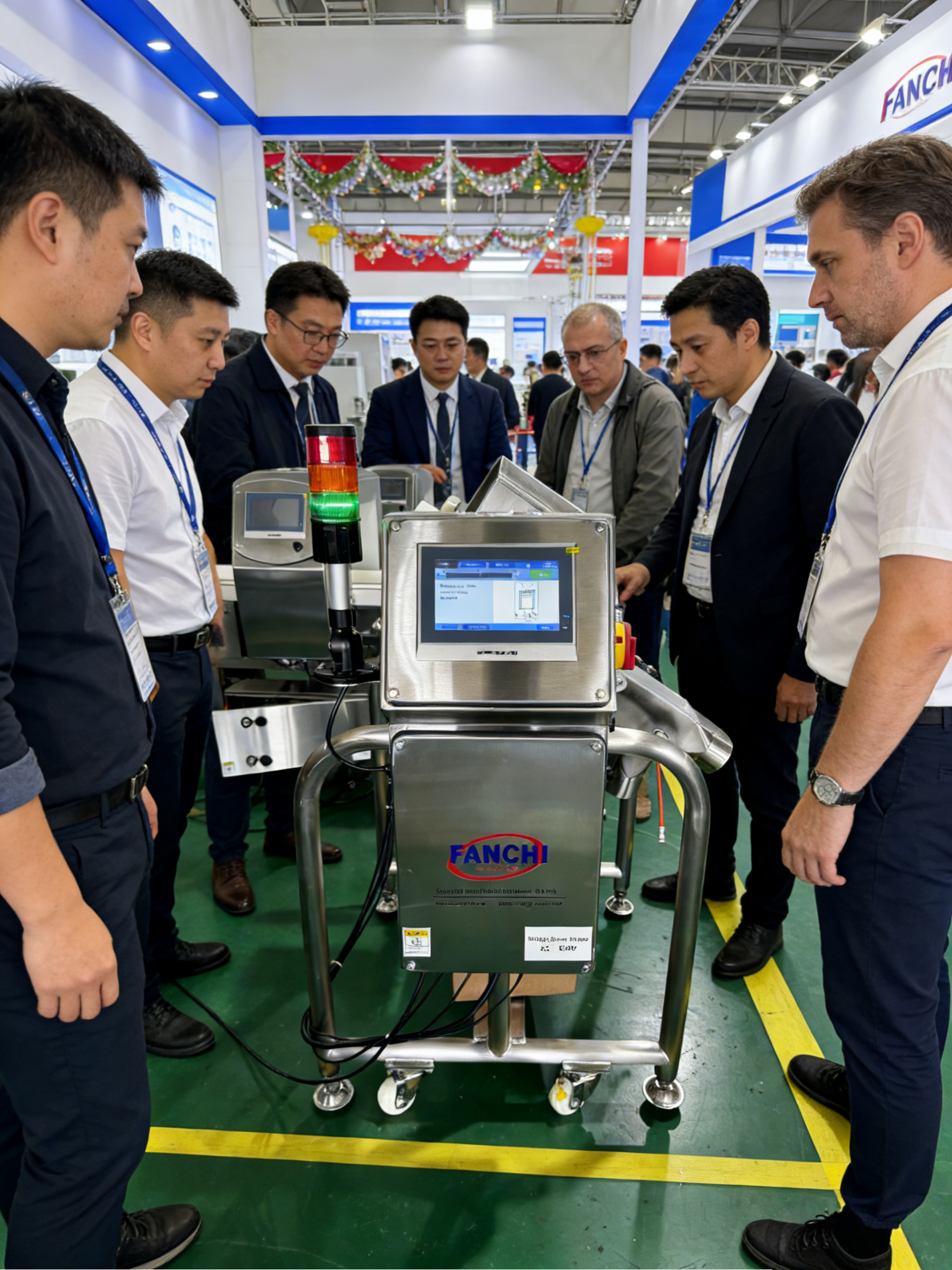

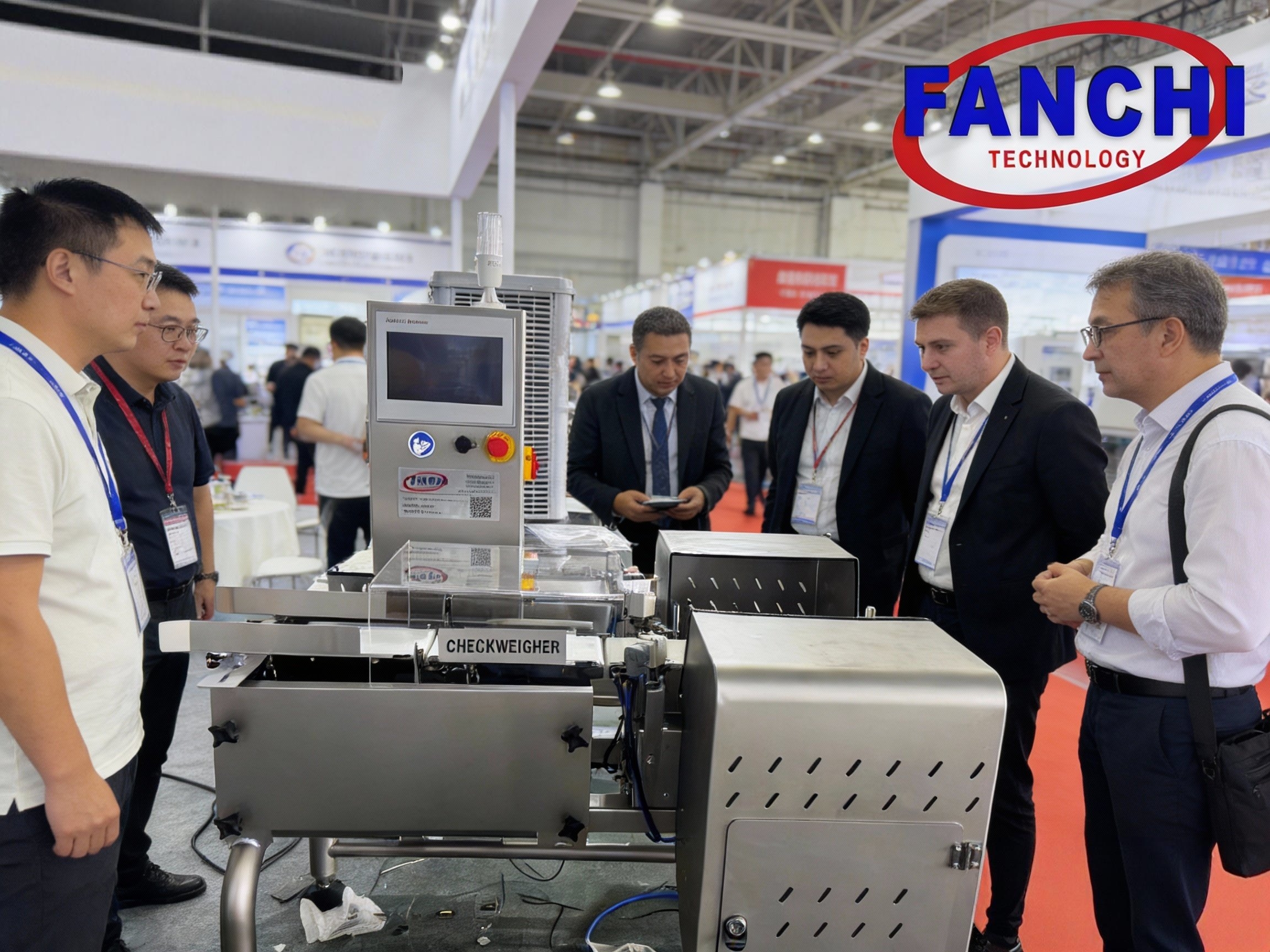

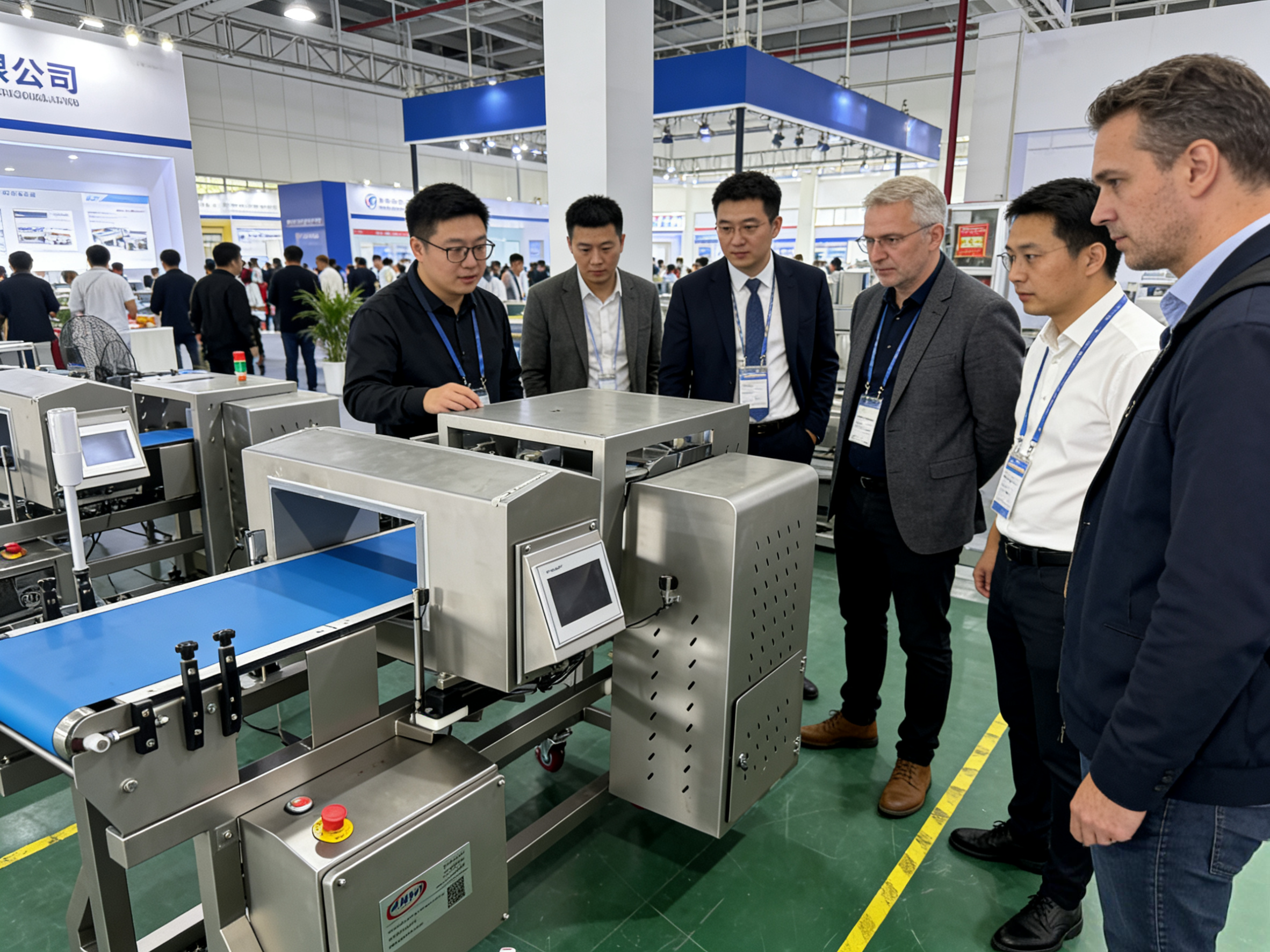

The Expo Showcase: Live Demos That Proved Performance

- FA-MD Metal Detectors:

We tested the unit with 15g mini almond crisp packs (the same small-format snacks from our BrightSnack case study) spiked with 0.5mm stainless-steel fragments. The FA-MD detected 100% of contaminants at 75 packs per minute—while avoiding false rejects from the high-fat product’s conductivity. A buyer from a German nut processor noted: “Our current detector misses 1 in 5 of these small fragments. This unit’s precision is exactly what we need.”

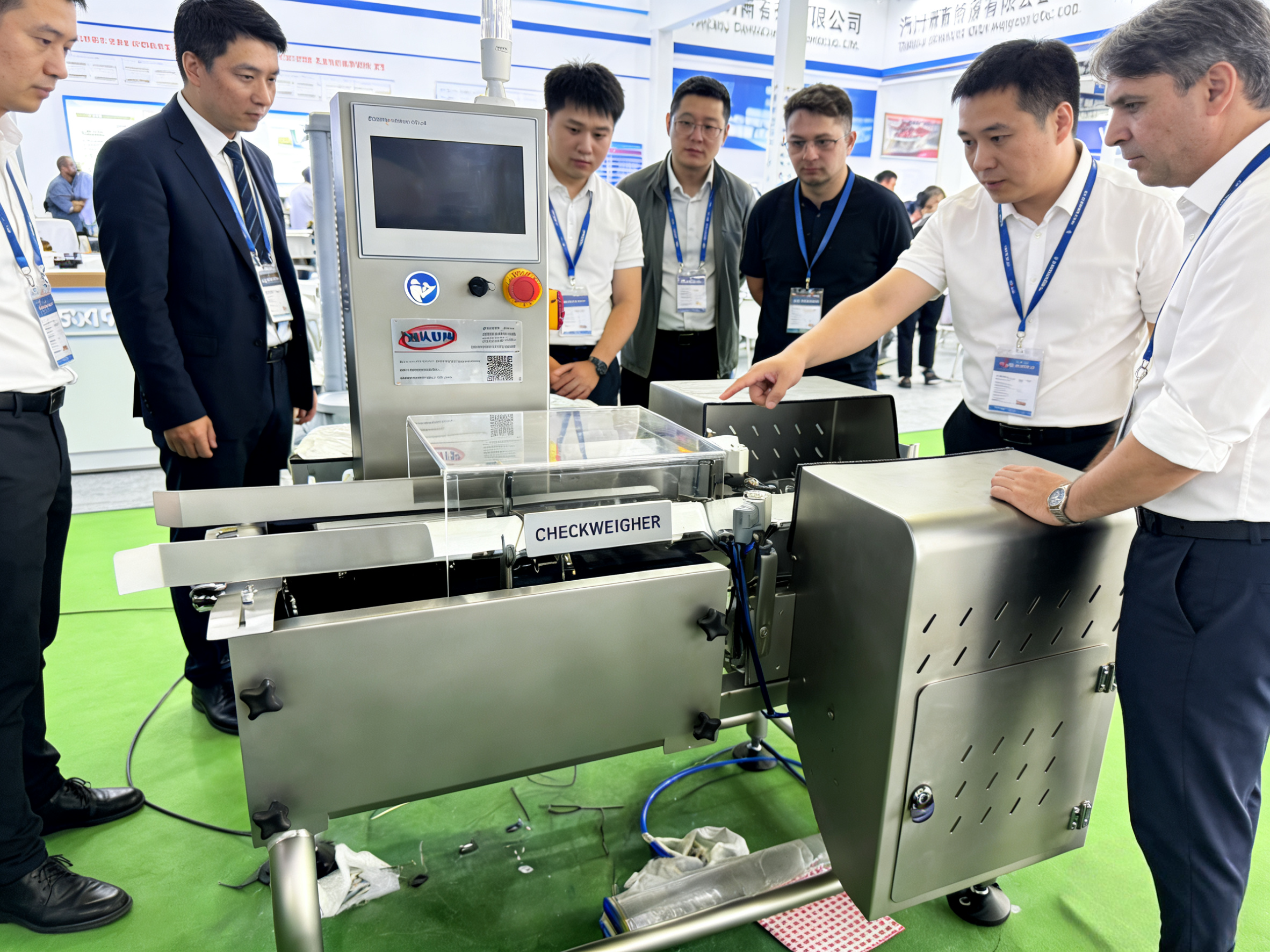

- FA-CW Checkweighers:

The demo simulated a 30g energy bar line, with the FA-CW verifying weights to ±0.6g accuracy (critical for EU weights-and-measures compliance). We also demonstrated the unit’s 30-second SKU switchover: operators called up a 5g seasoning sachet profile via the touchscreen, and the checkweigher auto-adjusted its conveyor speed and weight tolerance thresholds—impressing a French foodservice supplier who cited “10-minute changeovers” as their biggest operational pain point.

The Crowd: Who Came to See Fanchi-tech?

- 32 buyers from EU/US retail suppliers (including a quality manager from a UK snack conglomerate, who tested the FA-MD’s performance on chocolate-coated pretzel packs).

- 18 regional distributors (we signed 2 new partnerships for Southeast Asia and Eastern Europe, with a focus on dry food and snack production lines).

- 12 food safety auditors, who validated the FA-MD/FA-CW’s IP66 washdown rating and BRC-compliant design—critical for facilities requiring daily high-pressure cleaning.

The Outcome: Pre-Orders & Global Interest

- We secured 12 pre-orders (6 FA-MD units, 4 FA-CW units, 2 combo systems) worth $280,000, all from customers in the snack, cereal, and dry food sectors.

- 47 buyers requested on-site trials (including a Netherlands-based snack producer who booked a test for their 22-SKU mini cookie line).

- A Polish distributor signed a 3-year agreement to carry our FA-MD/FA-CW lines in Central Europe, with a focus on partnering with local bakery and snack manufacturers.

Why Fanchi-tech’s Expo Demo Resonated

- Small-Pack Precision: Focused on the tiny contaminants that plague snack producers, from blade shavings in nut processing to metal particles in seasoning mixes.

- Speed & Efficiency: Highlighted the 30-second SKU switchovers that cut downtime for facilities with diverse product lines.

- Hygiene Compliance: Let buyers inspect the FA-MD/FA-CW’s crevice-free stainless-steel build (critical for BRC/FSMA facilities that require strict sanitation protocols).

Next Steps: Schedule Your Own Demo

- Email: fanchitech@outlook.com

- Website: www.fanchitechnology.com

Post time: Jan-09-2026