-

Fanchi-tech Fully automatic X-Ray inspection liquid level detection machine for tin aluminum can beverage

Online detection and rejection of unqualified level and lidless products in bottle/can/box

1. Project name: Online detection of bottle liquid level and lid

2. Project introduction: Detect and remove the liquid level and lidless of bottles/cans

3. Maximum output: 72,000 bottles/hour

4. Container material: paper, plastic, aluminum, tinplate, ceramic products, etc.

5. Product capacity: 220-2000ml

-

Fanchi X-ray Inspection System Designed for Fishery Industry

Fanchi fish bone x-ray inspection system is a high configuration x-ray system designed specifically to find the tinies possible sizes of bones in fish portions or fillets, whether raw or frozen. Applying extremely high definition X-ray sensor and proprietary algorithms, the fish bone x-ray can detect bones down to 0.2mm x 2mm size.

The fish bone x-ray inspection system from Fanchi-tech is available in 2 configurations: either with a manual infeed/outfeed or with an automated infeed/outfeed. In both configurations, a large 40-inch LCD screen is provided, allowing an operator to easily remove any fish bones that are found, allowing the customer to salvage product with minimal loss. -

-

Fanchi-tech High performance conveying system

Fanchi’s extensive knowledge of the food, beverage and pharmaceutical industries has given us the edge when it comes to designing and building sanitary conveying equipment. Whether you are looking for complete wash-down food processing conveyors or stainless steel packaging conveyors, our heavy-duty conveying equipment will work for you.

-

-

-

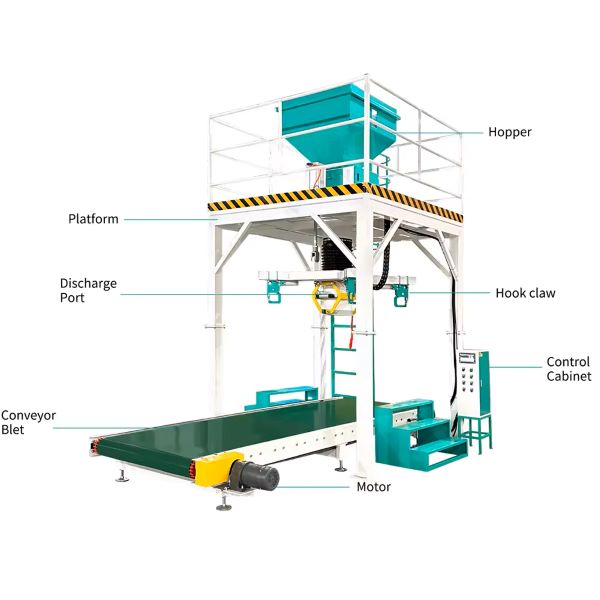

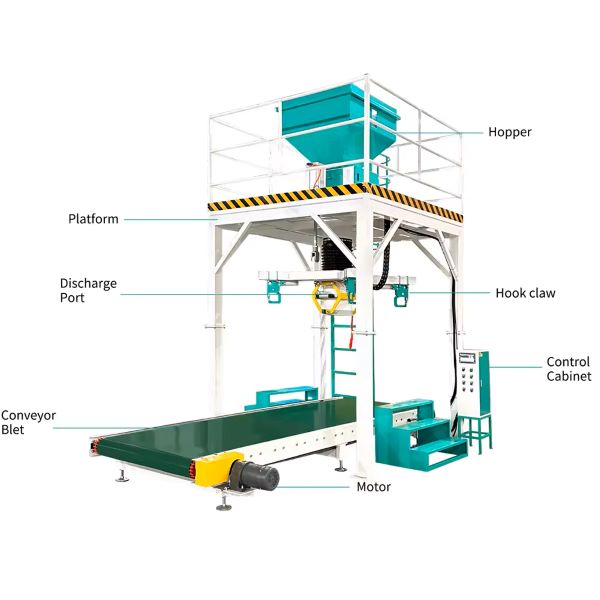

Fanchi Fully Automatic Granule Packaging Machine

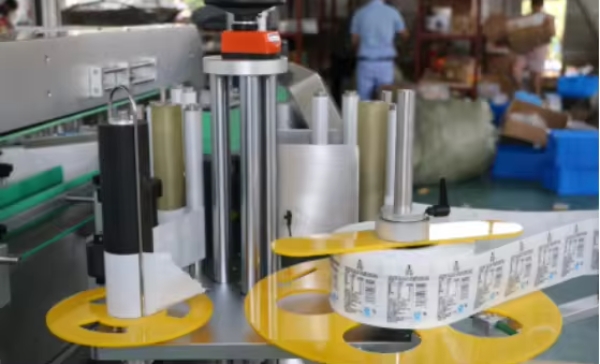

Fanchi FA-LCS series packing machine is suitable for pellet products, which can be accurate, rapidly weighing and packing, and is widely used in grain, feed, chemical and other fields. This product has good adaptability for a poor working environment. And there is a wide scope of weighing range, which can be packed arbitrarily within 5 ~ 50kg (just consider the size of the packaging bag opening). Weighing control adopts currently advanced performance software and hardware technology. The instrument itself has a good human -computer dialogue function, which is convenient for operators to modify relevant parameters and make the packaging work faster and more accurate.

-

Fanchi-Tech Ton Bag Packing Machine For Powders Granulers Bagging Machine

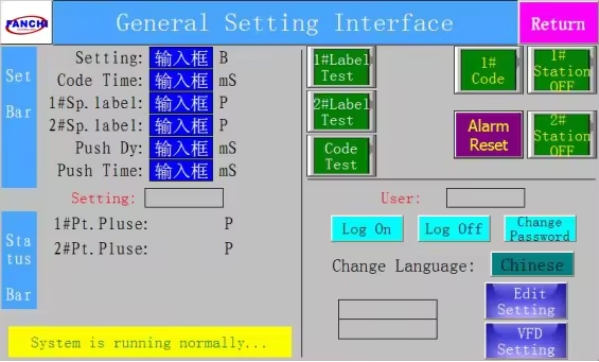

Fanchi Fully Auto packaging machine can be equipped with a net weight or gross weight weighing system. According to the characteristics of the material, the feeding method can be divided into self-falling + vibration feeding, free-falling, belt or screw conveying. It has strong adaptability and can use various types and specifications of packaging bags. The replacement of different specifications of packaging bags can be completed in a short time by the touch screen

-

Fanchi-tech Inline Metal Detector for Aluminum-Foil-Packaged Products

Traditional metal detectors are able to detect all conducted metals. However, aluminum is applied to packaging of many products like candy, biscuits, aluminum foil sealing cups, salt blended products, aluminum foil vacuum bag and aluminum containers, which is beyond the capability of traditional metal detector and leads to the development of specialized metal detector that can do the job.

-

FA-MD-B Metal Detector for Bakery

Fanchi-tech FA-MD-B Conveyor Belt Metal Detector is specially designed for products in bulk(non-packaged): Bakery, Confectionery, Snack Foods, Dried Foods, Cereals, Grains, Fruit, Nuts and Others. The pneumatic retracting belt rejector and sensitivity of the sensors make this an ideal inspection solution for bulk products application. All Fanchi metal detectors are custom-made and can be individually adapted to the requirements of the respective production environment.